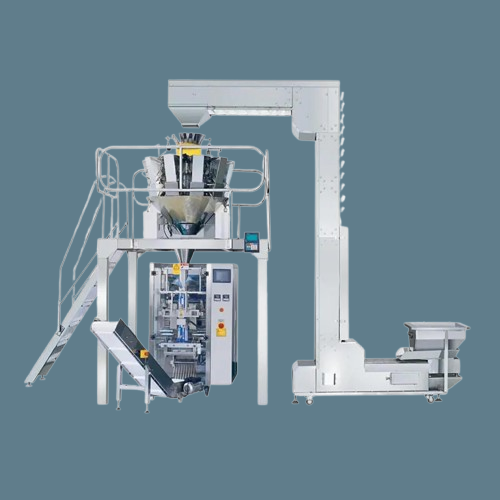

10 Head

Designed for high-speed, high-accuracy pouch packing, the Multihead Weigher Machine is an essential solution for large-scale production environments. Operating at an impressive 40–60 packs per minute, these machines have transformed the food and dry product packaging industry with their combination dumping technology—a method that ensures both speed and precision. Whether you're packing light snacks like wafers and namkeens or denser items like dry fruits and spices, this machine provides the reliability and consistency modern production demands. This machine is suitable for packing of : Snacks Items: Chips, namkeen , farsan, frymes,Popcorn etc. Grocery Items: Dals,Peanuts,sugar, nuts,Dry fruit,Whole Spices,Poha,murmura,etc Hardware Items : Nuts, Washers, screw, dowel Pins etc Confectionery Items: Chocolates, candies, toffees etc Frozen Foods: green peas, Chopped carrot, okra, prawns, shrimps etc.

Features

“Made In India” Multi head weigher, it incorporates the entire electrical, electronic , micro controller based system conceived designed, developed & manufactured in our state of art manufacturing facility.The software developed by our R & D team is incorporated in this machine.

The HMI (Human Machine Interface) is a large touch screen (Size 215 mm(W) x 160mm (H)x 60mm (D) with indigenously developed software

Motorized pulling system

Strip or individual count cutting provided.

Machine works on single phase.

In house manufacturing of all electronic control instruments.

This machine is suitable for packing of

Snacks Items: Chips, namkeen , farsan, frymes,Popcorn etc.

Grocery Items: Dals,Peanuts,sugar, nuts,Dry fruit,Whole Spices,Poha,murmura,etc

Hardware Items : Nuts, Washers, screw, dowel Pins etc

Confectionery Items: Chocolates, lollipop, candies, toffees etc

Frozen Foods: Chopped : Carrots, green peas, okra, pronze , shrimps etc.

further we have, in a bid to serve the industry, decided to provide retrofit services. This will help the multi head weighers which are under break down, to swing back into the action. We are open to supply multi head weigher system to OEMs to fit the same on their own VFFS machines.

Optional Accessories for FFS M/C

Nitrogen gas flushing unit

Hole punching unit

TTO for batch / date printing

Gusseting unit

Fast change of film roll unit

D cut

Benefits:

“Made in India” ensures virtual zero down time, means your machine keep working for you 24 X 7.

The machine provides leak proof pouches

Our nitrogen gas flushing unit guarantees near 100% (More than 99.5%) nitrogen in the pouch.

Thus increases the shelf life and quality of your product.

High rate of return on investment

Output to capital investment cost is low as compared to peer to peer comparison.

“Made in India” Multi head weigher ensures international quality standards and allows us to provide prompt after sales –service, quick supply of spares and flexibility in design to adopt changes as per customer requirement the one an only FFS Packaging Machine.

Low power consumption thus lowering running cost of machine.

Automated sensor system minimizes wastages of film and material.

We can customize our machine to suit your site condition such as height and width

No skilled operator required

Manpower saving.

Virtually all kind of granules products are handled by single machine.

Technical Specifications

|

Items to be Packed |

Granular, Fluffy, Irregular shaped, Solids |

|

Max Capacity |

5g- 1kg |

|

Accuracy |

0.1 – 1.5 gms |

|

Max Speed |

45-60 pouches per minutes* |

|

Pouch width |

50-250 mm |

|

Pouch length |

65 – 330 mm |

|

Film Width |

120 -530 mm |

|

Power requirement |

2KW, Single phase 230 VAC |

|

Material Construction |

All contact parts SS304, & other parts of MS |

|

Air Requirement |

2HP,8Bar Pressure.2 CFM |

|

Forming type |

Collar |

|

Horizontal seal width (mm) |

10/15 typical |

|

no of weighing Pan |

10no |

|

Dimension (W x H xD) in ft. |

7 x 11 x 6 (without Conveyor). |

|

Serration and cutting |

Count cutting provided, count to be fed through |

|

Control of FFS |

Through micro controller |

|

Eye mark controller |

Provided. |

|

Process parameter setting |

Through HMI. |

|

Film draw mechanism |

Through steeper/ servo motor |

|

Horizontal sealing mechanism |

Pneumatic |

|

Vertical seal mechanism |

Pneumatic |